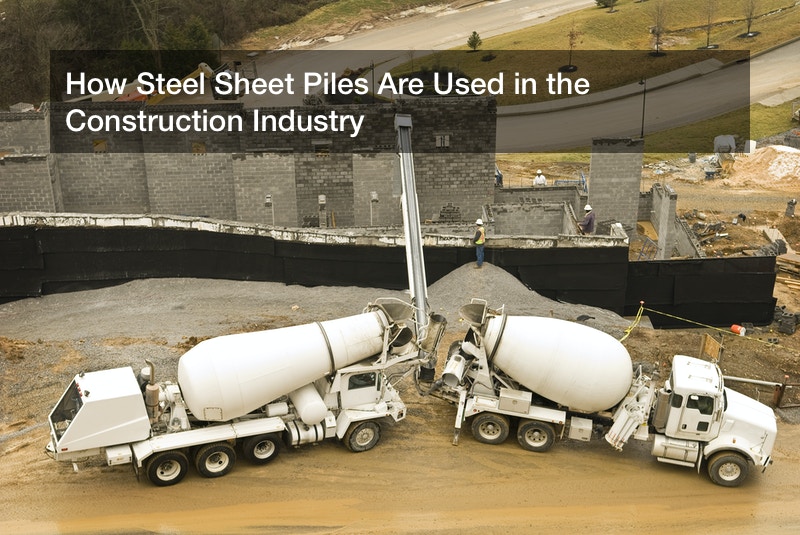

Steel has been used in construction since the nineteenth century, and it continues to be one of the most important metals used in the industry. Steel sheet piling is used in different kinds of building projects such as retaining walls, underground buildings, land reclamation, seawalls, riverside construction etc. It can be used for temporary support during construction or as a permanent feature. Each project is different, and the type of retaining system to be used must be designed by experienced sheet piling companies to meet the specific conditions.

Steel sheet piling in construction

Steel has long been used as basic material in the construction industry. Along with copper and aluminum, stainless steel and carbon steel are the most commonly used metals in construction in the U.S. The U.S. is one of the leading steel producers in the world, with output reaching 82 metric tons in 2017. The U.S. also imports steel, with about 43% of all imports going to the construction industry in 2016.

The importance of steel in construction lies in its strength. The tensile strength of carbon steel is 580 megapascals (Mpa) and its yield strength is 260 Mpa. Steel sheet piles are widely used in construction to form earth retaining walls in sandy, marine or riverside environments to prevent erosion. Sheet piles are long sections that are locked vertically to make a wall. There are various kinds of piling, suitable for different conditions.

Uses of steel sheet pilings

Steel sheet pilings can be used for temporary or permanent retaining structures. For temporary uses, they can be rented from sheet piling companies. The kind of sheet piling used in any project depends on local conditions. These conditions include:

- Site conditions like the type of soil, presence of water, etc.

- The amount of bending movements required

- The type of structure, eg. seawall, land reclamation project, underground parking garage, etc.

- The depth to which the piling must be installed

- The kind and amount of protection required

Besides preventing soil erosion, piles can also prevent ground water seepage into construction sites. Sheet piling companies can assess each project to help determine which type of steel sheet piling are suitable for a particular site and purpose.

Installation of steel sheet piles

Steel sheet piles form vertical interlocking walls that retain earth or water. The interlocks can be tighter or looser, depending on the type of sheet piles used. In general, hot rolled sheet piles, which are produced at high temperatures, have tighter interlocks than cold formed sheet piles. The piles are driven into the ground to support excavations. When driving conditions are hard due to the nature of the soil, hot rolled sheet piles with tight interlocking are used.

Sheets are inspected before installation. They are driven into the ground using vibratory hammers or impact hammers. They can also be installed using a hydraulic load system in environments where vibrations are risky. The piles can be cantilevered or supported with anchors or tie-backs.

Steel sheet pilings can be used for temporary or permanent support in construction. They form retaining walls to exclude soil or water from the site. Sheet piling companies can recommend the best type of sheet piles needed for each project, and provide complete services including rental, installation and removal upon completion of the project.